When you’re serious about welding—whether as a hobbyist or a professional—you need more than just the right torch and rod. A stable, precise workstation is essential. That’s where a quality welding table and reliable clamps come in. Here’s why they matter and which products stand out.

Why a Good Welding Table Matters

A dedicated welding table is built to withstand heat, electrical currents, and rigorous use. Unlike regular workbenches, welding tables are made from fireproof, electrically conductive materials—usually steel—and often feature hole grids or slots for fixture use Wikipedia. These features help with grounding and holding your workpiece securely, which is crucial for safety and weld quality Fireball ToolHà Bắc Hossmann. As one DIY welder shared on Reddit:

“Holes are not needed… If it’s not expensive for holes then get them. I would lay out 3/8in or 1/2in holes every inch… If you’re a hobbyist… weld fixtures on as needed.”

Clamps: The Unsung Heroes

Clamps play a vital role in keeping your workpieces steady and aligned. Without them, even minor shifts during welding can compromise the seam, produce defects, or cause accidents

Clamp types and uses:

- C-Clamps (or G-Clamps): Classic and versatile, ideal for general tasks The Spruce Wikipedia.

- Toggle Clamps: Provide quick, high-force holding for repetitive tasks Number Analytics.

- Bar Clamps: Great for longer workpieces, offering steady, distributed pressure Number Analytics.

What to Look for When Choosing Your Table and Clamps

For the Welding Table:

- Material & Flatness – Prefer steel tables with precision flatness for accurate welds.

- Hole Pattern – Spaced bore holes (e.g., 16 mm) give flexibility for clamping and fixtures WeldTables.com.

- Weight Capacity & Portability – Match the table’s strength and portability to your workspace and projects.

For Clamps:

- Strong, Durable Construction – Should withstand heat and pressure.

- Quick Adjustment & Release – Features like push-down mechanisms make setup faster (e.g., Inserta-style clamps).

- Compatibility with Table Holes – Ensure they fit your table’s hole sizes.

Recommended Products

Klutch Welding Table

- Features: Heavy-duty steel construction, 600 lb capacity, evenly spaced 16 mm holes (2 ” apart), 36 × 24 × 33 ” footprint This Old House.

- Why It Stands Out: Affordable, sturdy, and well-designed for stable welding setups. Users appreciate its balance of cost and functionality.

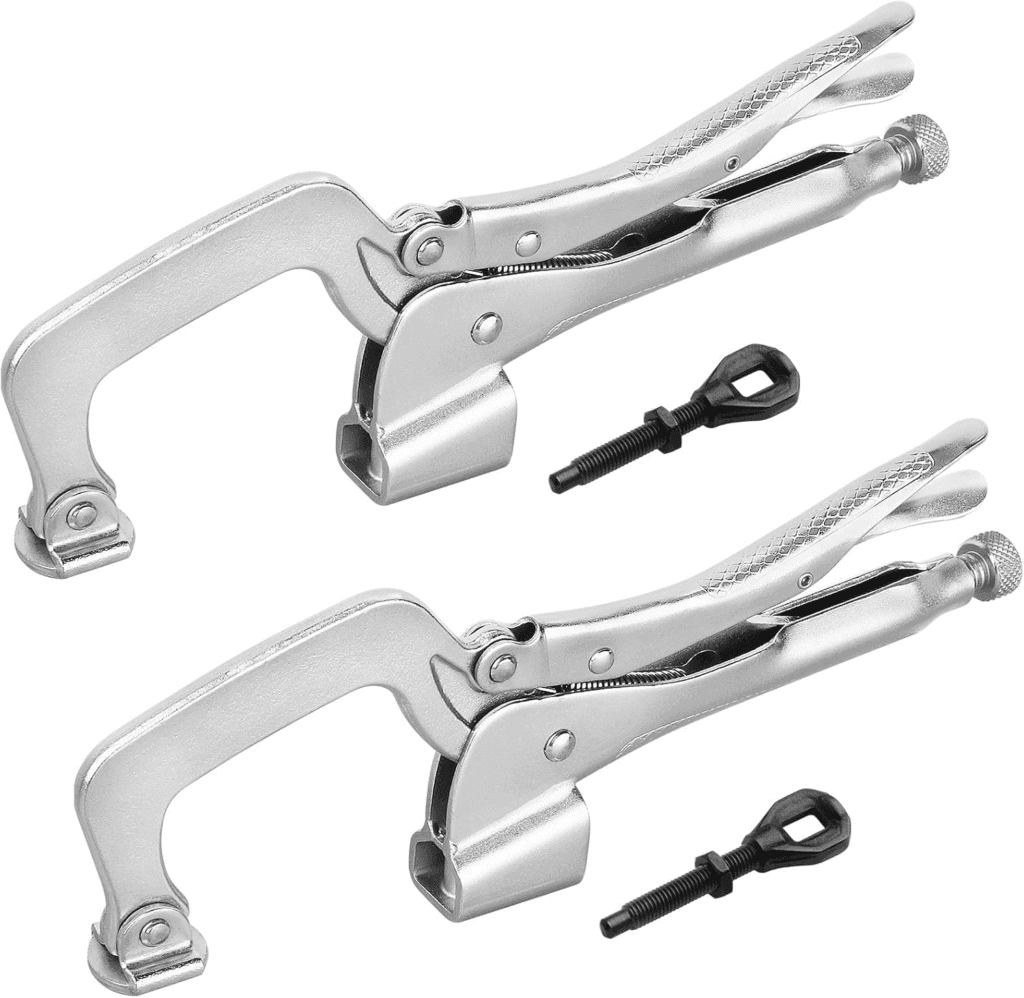

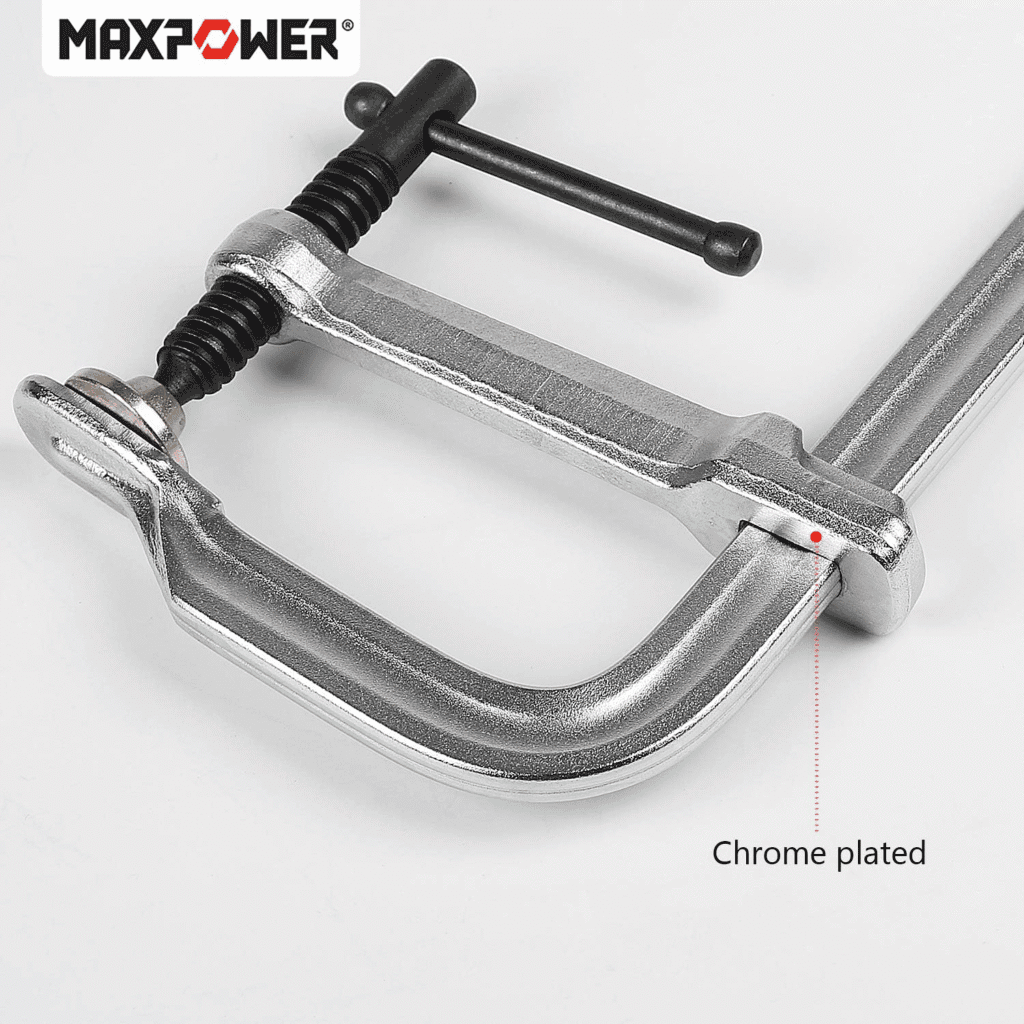

MAXPOWER Bench Clamp (Pack of 2)

- Features: Clamps that insert into tabletop holes (like 5/8″ or 16 mm), 4-inch max jaw, flat swivel pads, M8 bolt, quick-release trigger, adjustable pressure Amazon.

- Why It Stands Out: Secure and quick to position—perfect for frequent clamp adjustments on welding tables.

Putting It All Together

Setup Recommendations:

- Clean & Ground Properly – Ensure table surface and workpieces are free from rust or paint for solid electrical grounding Fireball Tool.

- Use the Table’s Hole Grid – Attach clamps precisely and adjust on the fly as needed.

- Clamp Strategically – Hold corners and edges stable; consider balancing pressure depending on material thickness and weld type.

Final Thoughts

A welding table like the Klutch Welding Table provides a flat, sturdy foundation built for heat and load. Pair it with MAXPOWER Bench Clamps, and you’ve got a flexible, secure setup that boosts accuracy and safety. Whether you’re crafting automotive brackets, metal art, or structural components, this combination offers superior control and stability in your workspace.

Leave a Reply